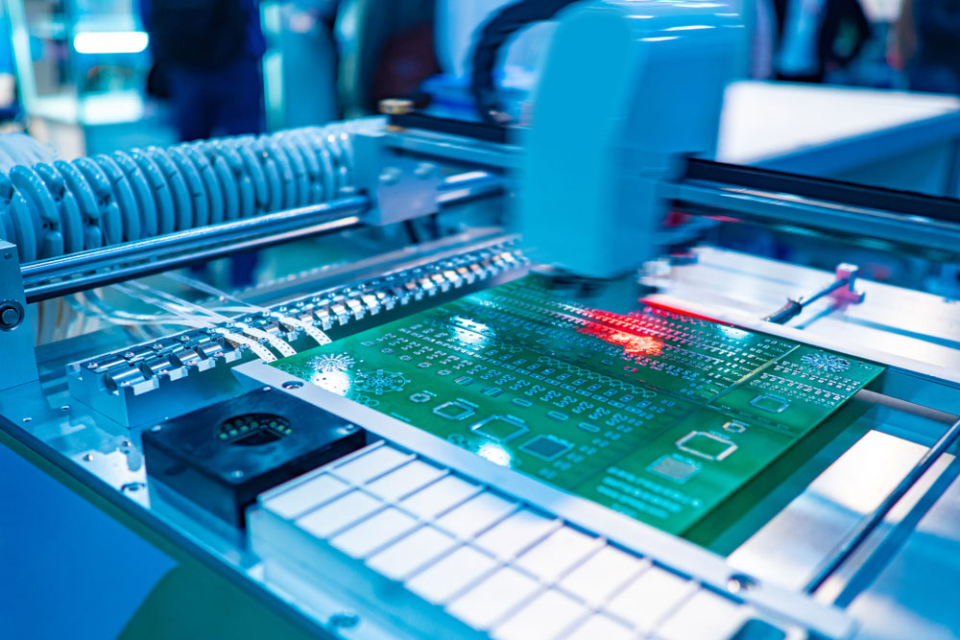

A prototype printed circuit board is an important step in the electrical item’s design process. Conductive tracks are used for a series of processes on printed circuit boards. Printed circuit boards are less expensive to manufacture than conventional circuit boards. There is no need for a complicated wiring process because they are published. Electronic design firms benefit from faster turnaround times because PCB manufacturing is far less labour-intensive than traditional circuit boards. PCBs are safer and more reliable because they lack wiring. They are also less susceptible to short-circuits. The use of PCBs also prevents wires from snapping or breaking free.

WHAT IS REQUIRED TO BUILD A PCB PROTOTYPE?

You must have the appropriate documentation in place before building your PCB prototype.

To ensure that your design is accurate, focus on creating readable and easy-to-follow documentation. Never let your PCB manufacturing documentation fall away. Some context should be included in your PCB documentation. This is especially important if your designs are for novel or proprietary technology solutions. Follow these steps to ensure your PCB manufacturing documentation is correct and to make the process as simple as possible for yourself:

- To save time, use templates.

- When using duplicates based on older documentation, be aware that all edits and deletions have been made.

- Make sure you have a review process in place to ensure accuracy.

- Check that all of your documentation coincides with the finished design.

- Check that part numbers are up to date.

What do you get when you hire Hiring for PCB Prototype services?

- 1 To 5 PCBs, single or up to 4 layers, in 3 to 4 working days.

- Completed PCB with two silk-screen and solder masks.

- The finish will be free of lead.

- Surface finishing options include nickel or lead-free HAL or gold immersion.

- Compliance with RoHS-FR4.

- There are no tooling fees or a minimum amount of PCBs required.

- Before production, perform a manufacturing check.

- Before pricing, use the PCB configuration tool to double-check the upload design parameters.

- PCB checker and visualizer for design analysis before placing an order.

WHERE CAN YOU GET YOUR PCB PROTOTYPE MADE?

With the coronavirus pandemic and the obstacles it has brought to industry and commerce, “ the capacity to manufacture your prototype PCB board has many advantages.

Because of the lack of tariffs, using Imagineering for your prototype and manufacturing will have faster turnaround times and lower costs. Contact China PCB today for a quote and to discuss your prototype and PCB manufacturing.

China PCB is one of the best places to get prototype printed circuit board assistance. China PCB provides its customers with simple, quick, no-hassle prototype PCB services. Expert employees analyze customers’ data, and its compliance with organizational policies and procedures, as well as technical specifications, is verified before circuit boards are sent to manufacturing for prototyping. Certain options, such as solder mask colors, finishing, via-filling, peel-able masks, and so on, are avoided because they are not necessary for creating a functional PCB prototype. This is the best strategy they use for timely and dependable fulfillment of customer orders at competitive rates.

ChinaPCBOne Technology LTD. is the author of this article on PCB prototype. Find more information, about China PCB.