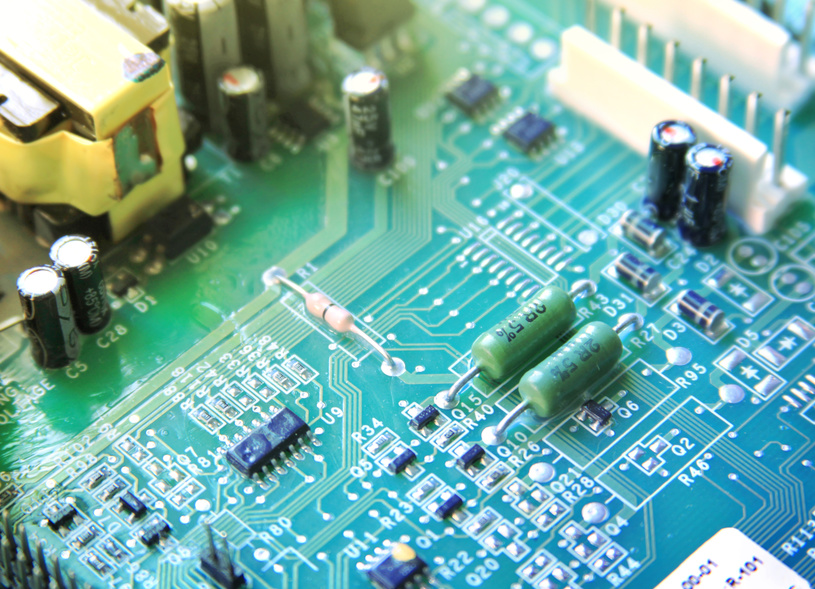

The printed circuit board manufacturing is a very comprehensive process that involves various stages of conceptualization, design, fabrication, assembly, and shipment of the final product. All of these stages are critical for the overall quality of the products and each stage requires expert handling of the processes. Amongst the different stages, the PCB fabrication is an integral component of the manufacturing process and needs to be taken care of expertly.

The PCB fabrication is essentially a procedure or a process which transforms the design of the circuit board into physical structure depending on specifications that are provided in design package. This instance of physical manifesting is generally achieved via different techniques. Some of these techniques or actions used for the physical manifestation are as follows. The imaging desired layout done on the copper clad laminates. Removing or etching the excess copper from the inner layers for revealing pads and traces.

Creating PCB layer stackup through laminating (pressing and heating) board materials at considerably high temperatures. Drilling hole for the mounting holes, via holes pins and the vias. Removing or etching excess copper from surface layers for revealing pads and traces. The addition of protective coating to the surface or the solder masking. The polarity indicators and silkscreen printing reference, logos, or other related markings on surface. Optionally, an additional finish can be done to the copper areas of the surface.

What to expect from ChinaPCBOne?

The ChinaPCBOne is one of the best PCB manufacturer in the market. The company is dedicated to offering one stop, turnkey solutions for various prototypes as well as small to medium volume production runs. The company provides expert consulting for design as well as manufacturing. The company has two factories that offer PCB design, assembly, manufacturing plus other services.

The ChinaPCBOne is responsible for managing low to mid level volume production runs from the assembly to the final shipment. ChinaPCBOne is also responsible for co-coordinating the entire process. The company completes the process including ordering components, design, assembly, manufacturing, and testing. You just need to provide the schematic design or idea and the company will take care of the rest. The customers are provided real products based on their specific designs. You can log on to the e-shop any time you want for obtaining the online quote. The company’s e-shop is available 24×7.

When it comes to the turnkey PCB assembly services, ChinaPCBOne provides both full as well as partial turnkey assembly to the customers. The company has collaborated with more than 3000 customers having 5000 different and varying electronic project requirements. A decade of experience in the industry means ChinaPCBOne can now one stop destination services that includes PCB manufacturing, assembly, and the component procurement to the customers. The assembly capabilities of ChinaPCBOne are BGA, SMT, Mixed, Through Hole, and Rigid Flex. The company’s products are compliant with the various industry standards including the IPC610 class 2 as well as class 3.